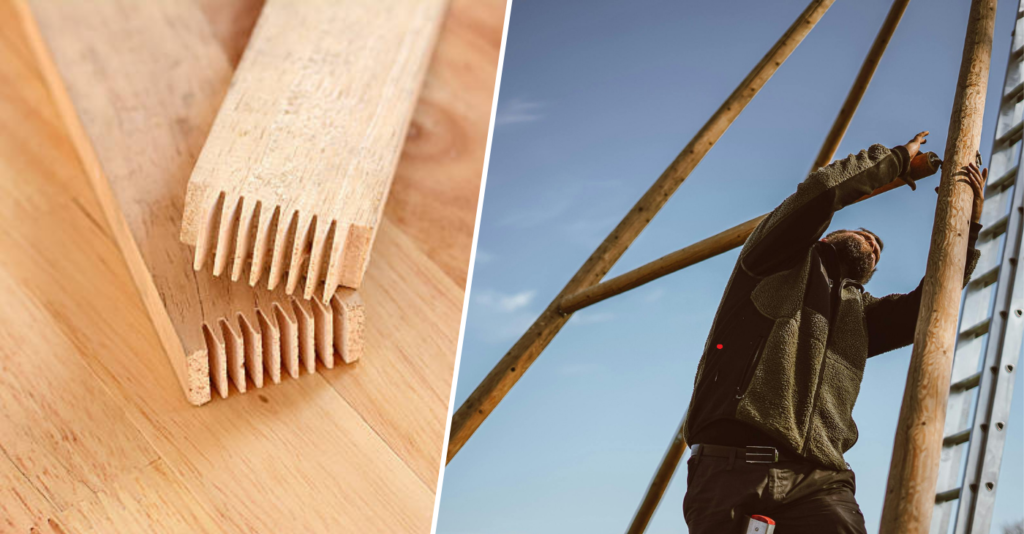

Timber frame joints – Build a solid foundation for your project

Why timber frame joints matter

Timber frame joints play a crucial role in holding the structure together. They connect the individual timbers to create a frame that can withstand loads. A well-made joint distributes the load evenly, reducing stress and ensuring that the frame remains stable.

Beyond their functional role, timber frame joints also add to the aesthetic appeal of a structure. Exposed joints, in particular, can showcase craftsmanship and enhance the visual appeal of the building. Understanding these joints will help you design both a strong and beautiful frame.

Key considerations when choosing timber frame joints

When selecting a joint, several factors should influence your choice:

- Load-bearing capacity: Choose a joint that can handle the loads it will need to bear. Some joints are better suited for heavy loads, while others are ideal for lighter applications.

- Aesthetic value: Some joints are exposed and become part of the design, while others are hidden. Consider the look you want when choosing your joints.

- Skill level: Some joints are more complex than others. If you’re a beginner, start with simple joints before attempting more intricate designs.

- Timber type: The type of timber used affects how well the joint performs. Hardwoods support more complex joints, while softwoods may require simpler connections.

- Environmental conditions: If your structure will be exposed to the elements, choose joints that will hold up under harsh conditions and protect the timber from moisture.

Types of timber frame joints

Timber frame joints are essential for both the strength and look of a structure. There are various types of joints, each serving a specific purpose. Here’s a breakdown of some of the most common timber frame joints, along with their pros and cons.

1. Mortise and tenon joint

The mortise and tenon joint is one of the oldest and most popular. It involves a “tenon” (a rectangular piece) on one timber that fits into a “mortise” (a hole) in another. This joint is great for resisting both tension and compression. The mortise and tenon joint has high load-bearing capacity and works well for both visible and hidden connections, providing a secure fit without requiring additional fasteners. However, it requires precise cutting, making it labor-intensive and challenging for novice builders.

2. Dovetail joint

Dovetail joints are used when two pieces meet at a right angle. The interlocking “tails” and “pins” create a strong connection, making it ideal for areas under tension, like corners. Dovetail joints offer excellent tensile strength and aesthetic appeal, especially for exposed joints, and are ideal for resisting lateral forces. On the downside, they are complex, time-consuming to cut, and require precise fitting, which may be difficult for less experienced builders.

3. Lap joint

A lap joint is simple. Two timbers overlap and are fastened together. A half-lap joint is a variation where half the thickness of each piece is removed so they fit flush. Lap joints are simple to create and do not require advanced tools or techniques, making them an excellent choice for beginners. They work well in lightweight construction but are not as strong as other joints and may require additional fasteners for reinforcement.

4. Scarf joint

A scarf joint is used to extend the length of timber. It involves cutting sloping surfaces at the ends of the timbers and fastening them together, often used in long beams or rafters. Scarf joints are ideal for extending the length of timber without compromising the structure’s integrity. They also provide a smooth, continuous appearance. However, aligning the timbers properly can be challenging, and the joint may require reinforcement for added strength.

5. Bridle joint

A bridle joint is like a mortise and tenon joint, but the mortise is an open slot at the end of the timber. It’s often used for joining posts and beams at right angles, especially when large loads need to be transferred. Bridle joints provide a strong and stable connection for load-bearing structures and are simpler to cut than mortise and tenon joints. However, the joint lines are visible, which may not be desirable for some designs, and the joint requires precise cutting for a snug fit.

6. Timber frame pegged joint

Pegged joints are traditional and involve driving wooden pegs through mortise and tenon connections. No nails or screws are needed, making this a sturdy, long-lasting method. Pegged joints offer a traditional, rustic appearance and create a strong, secure connection without the use of metal fasteners. They can also be disassembled if necessary. With its rustic charm and solid construction, a timber frame house blends seamlessly into both rural landscapes and modern urban settings. However, the wooden pegs may loosen over time, requiring maintenance, and precise drilling is required to ensure proper alignment.

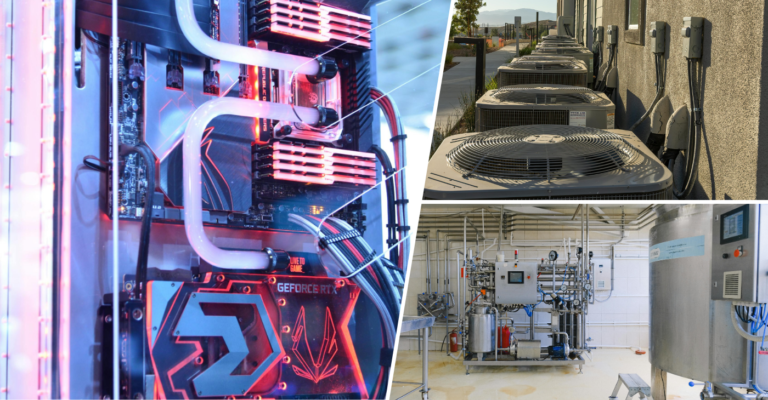

Traditional vs. modern timber frame joints

Traditional timber frame joints, such as the mortise and tenon, rely purely on the precise fit of the timbers for strength, offering an authentic, rustic appearance that has been used for centuries. These joints take more time and skill to craft but are valued for their craftsmanship and timeless look. In contrast, modern timber frame joints often incorporate metal fasteners or brackets, making construction faster and more durable. This approach is ideal for larger, more complex structures where efficiency and strength are crucial, though it may lack the traditional aesthetic appeal.

How timber frame joints enhance structural integrity

Timber frame joints are crucial for the stability of a building. They connect different pieces of wood, allowing the frame to support heavy loads and resist external forces. Joints like mortise and tenon, dovetail, and lap joints distribute weight evenly, preventing stress on any single point. This balance keeps the frame strong, even under pressure. Properly fitted joints also ensure the timber pieces stay securely in place. The right joint can make a structure more durable, helping it withstand weather, shifting, and time.

Are timber frame joints suitable for DIY projects?

Yes, many timber frame joints are suitable for DIY projects. Simple joints like lap or bridle joints are great for beginners. These joints don’t require advanced tools or high-level skills. However, more complex joints like mortise and tenon may require precise cutting and extra practice. With the right tools and patience, DIY builders can master these techniques. Plus, many online tutorials and guides can help beginners get started. Timber frame joints are a rewarding project for those looking to create strong, lasting structures.

How to build a solid foundation with timber frame joints

Building a solid foundation with timber frame joints involves careful planning and execution. Here’s how to approach the process:

- Plan the layout:

Start with a detailed plan that shows the placement of every timber. Identify which joints will be used at each connection. - Choose the right timber:

High-quality timber is essential. Look for wood with few knots or defects. Hardwoods like oak are ideal for load-bearing joints. - Cut precise joints:

Whether using hand tools or power tools, accuracy is crucial. Measure and cut your joints carefully to ensure they fit snugly. - Dry fit:

Before final assembly, do a dry fit of your joints. This will help you check the alignment and make any adjustments before committing. - Assemble carefully:

Once you’re confident everything fits, assemble the frame. Use wooden pegs, metal fasteners, or brackets depending on the joint type. - Reinforce as necessary:

In larger structures, you may need to reinforce key joints with metal connectors for added strength. - Protect the timber:

Apply a finish to the wood to protect it from moisture and other environmental factors. This will extend the life of your joints and prevent them from weakening.

How environmental conditions affect timber frame joints

Environmental conditions play a big role in how timber frame joints perform over time. Humidity can cause timber to swell, while dry conditions may lead it to shrink. This expansion and contraction can loosen joints if they aren’t properly protected. Extreme temperature changes can also impact the wood’s strength and the joint’s fit. Moisture is a key concern, as it can lead to rot or decay, especially if the wood isn’t treated. Regular maintenance, like sealing and treating the timber, helps keep joints strong in varying conditions.

How these joints contribute to sustainable construction

Timber frame joints support sustainable construction in several ways. First, timber is a renewable resource, especially when sourced from responsibly managed forests. Using traditional joints, like pegged joints, reduces the need for metal fasteners or adhesives, cutting down on materials that are harder to recycle. Timber frames also tend to be energy-efficient, as the wood provides natural insulation. When combined with durable joints, timber structures last longer, reducing the need for frequent repairs or replacements. This makes timber framing an eco-friendly choice in construction.